Choosing the Right AR-15 Barrel: A Comprehensive Guide

Choosing the right AR-15 barrel is crucial for optimizing your rifle's performance, longevity, and compliance with regulations. This comprehensive guide will explore the various AR-15 barrel types, materials, finishes, and compatibilities to help you make an informed decision. Understanding the legal barrel length for an AR-15 and how many rounds an AR-15 barrel will last is essential for legal compliance and practical use. We'll delve into the specifics, discussing the best AR-15 barrel material and steel options available. Additionally, we'll cover technical aspects such as the size of threads on an AR-15 barrel. Whether you are a seasoned enthusiast or a beginner, this guide will equip you with the knowledge to choose the perfect barrel for your AR-15.

Barrel Length and Profile

The barrel length of an AR-15 significantly impacts its performance. Longer AR-15 barrels generally increase bullet velocity, enhancing accuracy and effective range and making the rifle less maneuverable. Conversely, shorter barrels are more compact and easier to handle in tight spaces but sacrifice some velocity and range.

Barrel profiles, such as heavy, medium, and lightweight, further influence the rifle's performance. Heavy barrels offer improved accuracy and heat dissipation due to increased mass, making them ideal for sustained firing and precision shooting. However, they add considerable weight, which can be a drawback for extended use. Medium profiles balance accuracy and weight, providing good performance without excessive weight. Lightweight barrels are more accessible to carry and maneuver, making them suitable for dynamic shooting scenarios, but they may suffer from reduced accuracy and quicker heat buildup during rapid fire.

Choosing the right barrel length and profile depends on the intended use, balancing the need for accuracy, weight, and maneuverability.

Barrel Material

Choosing the suitable barrel material for your AR-15 is crucial for optimizing performance, durability, and handling. While many materials are available, the most popular include stainless steel, chrome-lined steel, nitride, and carbon fiber, each with advantages and disadvantages.

Stainless Steel: Known for its excellent accuracy and resistance to corrosion, precision shooters favor stainless steel barrels. They offer superior durability and are less rust-prone, making them ideal for harsh environments. However, they are heavier and may wear out faster under rapid, sustained fire than chrome-lined barrels.

Chrome-Lined Steel: These barrels are renowned for their durability and heat resistance. The chrome lining provides excellent protection against corrosion and wear, extending the barrel's lifespan, even with extensive use. While they may not offer the same level of precision as stainless steel barrels, their longevity and reliability make them a popular choice for military and tactical applications.

Nitride: Nitride barrels are treated with a chemical process that hardens the surface, improving wear resistance and corrosion protection. This treatment provides a smoother, more rigid surface than chrome lining, enhancing barrel life without significantly impacting accuracy. Nitride barrels offer a good balance of durability and performance at a lower cost than stainless steel and chrome-lined barrels.

Carbon Fiber: Lightweight and highly durable, carbon fiber barrels offer exceptional heat dissipation, reducing the risk of overheating during rapid fire. They are significantly lighter than traditional steel barrels, enhancing maneuverability and reducing shooter fatigue. However, they are often more expensive and may provide a different level of accuracy than high-quality stainless steel barrels.

These are among the most popular AR-15 barrel materials, but other options are available. Each material has its strengths, and the best choice depends on your specific needs: precision, durability, weight reduction, or cost-effectiveness.

Barrel Twist Rate

The twist rate of an AR-15 barrel is a critical factor in bullet stabilization and accuracy. Twist rate refers to the distance a bullet must travel to complete one full rotation, expressed as a ratio (e.g., 1:7 or 1:9). A faster twist rate (e.g., 1:7) means the bullet rotates more quickly, essential for stabilizing heavier, longer bullets. Conversely, a slower twist rate (e.g., 1:9 or 1:12) is suitable for lighter, shorter bullets. For more information on AR15 barrel twist, check out this AR-15 barrel twist rate chart.

Impact on Bullet Stabilization and Accuracy: Proper bullet stabilization is crucial for maintaining accuracy. An unstable bullet may wobble or tumble, leading to poor performance.

Recommended Twist Rates Based on Intended Use:

- Close-Quarters Combat (CQB): A 1:9 or 1:8 twist rate stabilizes standard 55-62 grain bullets, ideal for short-range engagements.

- General Purpose: A 1:8 twist rate balances stabilizing a wide range of bullet weights (55-77 grains) for versatile use.

- Long-Range Shooting: A 1:7 twist rate is optimal for heavier bullets (69-80 grains), maintaining velocity and accuracy over long distances.

Choosing the appropriate twist rate based on your AR-15's intended use ensures optimal performance and accuracy.

Gas System

The gas system length of an AR-15 significantly impacts its reliability, recoil, and cyclic rate. There are three main gas system lengths: carbine, mid-length, and rifle.

Carbine: The shortest gas system, carbine length, is typically around 7.5 inches. It generates higher gas pressure, resulting in a faster cyclic rate and increased recoil. While reliable in shorter barrels, it can be harsh on the internal components, leading to quicker wear. This system is ideal for compact, close-quarters setups where maneuverability is crucial.

Mid-Length: Measuring around 9 inches, the mid-length gas system balances the carbine and rifle systems. It provides a smoother shooting experience with reduced recoil and stress on components. This system is suitable for barrels around 14.5 to 16 inches, making it a popular choice for general-purpose and recreational shooting.

Rifle: The most extended gas system, typically 12 inches, is used in rifle-length barrels of 18 inches or more. It generates the least amount of recoil and has the slowest cyclic rate, enhancing reliability and reducing wear on components. This system is ideal for precision shooting, competition, and hunting, where accuracy and smooth operation are paramount.

Choosing the Appropriate Gas System:

- Competition: A mid-length or rifle gas system is preferred for its balance of recoil and reliability.

- Hunting: A rifle gas system offers the best accuracy and smooth operation for long-range shots.

- General Purpose: A mid-length system provides versatility and a comfortable shooting experience.

- Close-Quarters Combat: A carbine-length system suits compact, maneuverable rifles.

Selecting the appropriate gas system length for your intended use ensures optimal performance and shooting experience.

Chamber and Bore

Understanding the chamber and bore specifications of your AR-15 is crucial for ensuring compatibility with ammunition and optimizing accuracy.

Chamber Specifications:

- .223 Remington: Designed for civilian use, this chamber is tailored for .223 Remington ammunition. While highly accurate, it has a lower pressure tolerance than 5.56 NATO chambers. Using 5.56 NATO ammo in a .223 Remington chamber can increase pressure and potential safety issues.

- 5.56 NATO: This military-specified chamber can safely fire 5.56 NATO and .223 Remington ammunition. Its higher pressure tolerance and slightly looser dimensions make it more versatile and reliable, especially in demanding conditions.

- .223 Wylde: A hybrid chamber, .223 Wylde combines the tight tolerances of .223 Remington with the pressure tolerance of 5.56 NATO. It allows safe use of both ammunition types while offering improved accuracy over a standard 5.56 NATO chamber.

Bore Specifications:

- .223 Wylde: This cartridge is designed to maximize accuracy with both .223 Remington and 5.56 NATO ammunition. The .223 Wylde bore offers a tighter freeborn and throat, enhancing precision without sacrificing safety or compatibility. This makes it popular for competitive shooters and those seeking superior accuracy across different ammo types.

Benefits of Bore Specifications:

- Accuracy: Bore specifications like .223 Wylde are engineered to provide tighter groups and better consistency, particularly with high-quality match-grade ammunition.

- Versatility: Chambers like .223 Wylde offer the flexibility to shoot both .223 Remington and 5.56 NATO rounds accurately, making them ideal for various shooting applications, from hunting to competitive shooting.

Choosing the right chamber and bore specifications ensures optimal performance, safety, and versatility, allowing you to make the most of your AR-15 in any shooting scenario.

Accuracy and Precision

Several key factors influence the accuracy and precision of an AR-15 barrel, including manufacturing quality, rifling method, and crown quality.

Manufacturing Quality: The overall quality of barrel manufacturing is paramount. High-quality materials and meticulous craftsmanship result in a barrel that performs consistently and reliably. Precision machining and attention to detail during production reduce imperfections that can negatively impact accuracy.

Rifling Method:

- Button Rifling: This method involves pulling or pushing a button through the barrel to form the rifling. It's popular due to its cost-effectiveness and ability to produce consistent results. However, the process can induce stress in the barrel, potentially affecting accuracy.

- Cut Rifling: Grooves are cut into the barrel using a cutting tool. This process is slower and more labor-intensive but produces precise rifling with minimal stress on the barrel, leading to enhanced accuracy.

- Hammer Forged: This method uses a mandrel with a rifling pattern, around which the barrel is hammered into shape. Hammer-forged barrels are highly durable and accurate, though the process can sometimes lead to minor internal imperfections.

Crown Quality: The crown is the muzzle end of the barrel where the bullet exits. A well-crafted crown ensures that gas escapes evenly around the bullet as it exits, preventing destabilization. Any imperfections in the crown can significantly impact accuracy, making a high-quality, uniform crown essential for optimal performance.

Assessing Potential Accuracy:

- Reviews: Reading reviews from other shooters and experts can provide valuable insights into a barrel’s real-world performance. Look for consistent praise or recurring issues.

- Manufacturer Reputation: Established manufacturers with a history of producing accurate and reliable barrels are generally a safer bet. Brands known for their precision engineering and quality control are likelier to make barrels that meet high accuracy standards.

- Barrel Specifications: Consider specifications like the rifling twist rate, material, and bore/chamber dimensions. Detailed specifications can indicate the barrel’s intended use and performance characteristics.

Considering these factors, you can assess a barrel's potential accuracy and make an informed decision that aligns with your shooting needs and goals.

Barrel Coatings and Finishes

Choosing the suitable barrel coating and finish is essential for ensuring the longevity, performance, and aesthetics of your AR-15. Standard coatings such as phosphate, nitride, and chrome each offer distinct benefits regarding corrosion resistance, lubricity, and durability.

Phosphate Coating: Also known as Parkerizing, phosphate coating is a traditional method for protecting barrels from corrosion and wear. It provides a matte, dark finish that reduces glare and is relatively easy to apply. Phosphate-coated barrels are durable and affordable but require regular maintenance and oiling to prevent rust.

Nitride Coating: Nitride, or ferritic nitrocarburizing, is a chemical process that hardens the surface of the barrel, significantly improving wear and corrosion resistance. Nitride coatings offer excellent lubricity, reducing friction and the need for frequent lubrication. The finish is typically smooth and glossy, with a deep black color that enhances the barrel's aesthetics. Nitride barrels are known for their durability and low maintenance requirements, making them popular for shooters.

Chrome Lining: Chrome-lined barrels are known for their exceptional durability and heat resistance. The chrome lining provides a hard, smooth surface inside the barrel, which reduces wear and enhances corrosion resistance. Chrome-lined barrels can handle high rates of fire and extended use without significant degradation. However, due to the slight variations in the lining thickness, they may not offer the same level of precision as nitride or unlined barrels. Chrome-lined barrels typically have a shiny, reflective finish that can be visually striking.

Impact of Finishes on Aesthetics and Maintenance:

- Aesthetics: The choice of finish can significantly affect the appearance of your AR-15. Phosphate coatings provide a rugged, non-reflective look, while nitride finishes offer a sleek, modern appearance. Chrome-lined barrels can add a polished, professional look to your rifle.

- Maintenance Requirements: Phosphate-coated barrels require regular oiling and maintenance to prevent rust. With their excellent corrosion resistance and lubricity, nitride barrels require minimal maintenance, making them ideal for shooters looking for low upkeep. Chrome-lined barrels, while durable, also benefit from regular cleaning to maintain their performance and appearance.

Selecting the appropriate coating and finish for your AR-15 barrel ensures optimal performance, durability, and aesthetics tailored to your needs and preferences.

Installation and Maintenance

Proper installation and maintenance of your AR-15 barrel are crucial for optimal performance, safety, and longevity. Here are some tips to help you install your barrel correctly and maintain it effectively.

Installation Tips:

- Tools and Safety: Gather necessary tools, including a barrel nut wrench, torque wrench, vise, and receiver block. Please make sure your workspace is clean and well-lit. Always wear safety glasses to protect your eyes from debris.

- Receiver Preparation: Secure the upper receiver in a vise using a receiver block to prevent damage. Please make sure it is stable and won't move during installation.

- Barrel Installation: Align the barrel extension with the receiver and slide the barrel into place. Ensure a snug fit without forcing it. Apply anti-seize compound to the barrel nut threads to prevent galling and ease future removal.

- Torque the Barrel Nut: Hand-tighten the barrel nut, then use a torque wrench to tighten it to the manufacturer's specified torque value, typically between 30-80 ft-lbs. Tighten the nut in stages, loosening and retightening three times to ensure proper alignment and even pressure.

- Gas Block and Tube: Install the gas block and tube, ensuring proper alignment with the barrel's gas port. Secure the gas block using set screws or pins. Check for adequate gas tube alignment with the upper receiver's gas key.

- Final Checks: Reassemble the upper receiver and perform a function check to ensure smooth operation. Could you verify the bolt carrier group moves freely and that the gas system is correctly aligned?

Maintenance Guidelines:

- Regular Cleaning: Clean the barrel after each use to remove fouling, powder residue, and debris. Use a bore brush, cleaning rod, and appropriate solvent to scrub the barrel's interior. Follow up with patches until they come out clean.

- Lubrication: Apply a light coat of gun oil to the barrel's interior and exterior to prevent rust and corrosion. Please ensure the gas block and tube are lightly lubricated for smooth operation.

- Inspect for Wear: Inspect the barrel for signs of wear, pitting, or damage. Pay attention to the muzzle crown, gas port, and chamber areas. Address any issues promptly to prevent further damage.

- Proper Storage: Store your AR-15 in a cool, dry place to prevent moisture buildup and corrosion. Use a gun case or safe with a dehumidifier to maintain optimal conditions.

- Avoid Overheating: Allow the barrel to cool down periodically during extended shooting sessions to prevent overheating and potential damage. Overheating can accelerate wear and affect accuracy.

- Use Quality Ammunition: Use high-quality, factory-loaded ammunition to reduce the risk of fouling and excessive wear. Avoid using corrosive or substandard ammunition that can damage the barrel.

By following these installation and maintenance guidelines, you can ensure your AR-15 barrel performs reliably and maintains its accuracy over its lifespan.

Accessories and Compatibility

When selecting an AR-15 barrel, it's essential to consider the compatibility and impact of various accessories, such as muzzle devices, handguards, and other AR-15 components, like upper receivers and gas blocks.

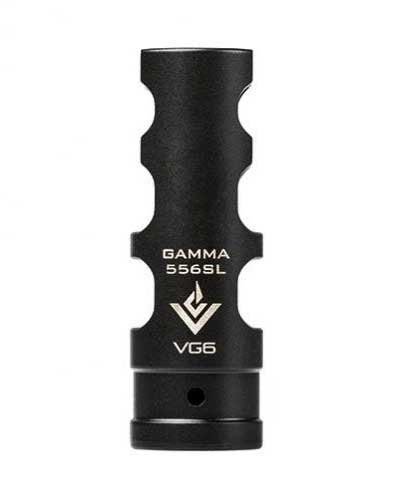

Muzzle Devices:

- Flash Hiders: These devices reduce the visible flash when firing, improving visibility and reducing night blindness. Ensure the barrel has the correct thread size (e.g., 1/2x28) to accommodate the flash hider.

- Muzzle Brakes: Designed to reduce recoil and muzzle rise, muzzle brakes can significantly affect shooting comfort and accuracy. Verify that your barrel’s threading matches the muzzle brake specifications.

- Suppressors: If you plan to use a suppressor, ensure your barrel is compatible with the suppressor's mounting system. Some suppressors require specific thread pitches or quick-attach systems.

Handguards:

- Free-Float Handguards: These handguards attach directly to the upper receiver, not the barrel, allowing for better accuracy by reducing barrel flex. Ensure your barrel is compatible with the free-float handguard's mounting system.

- Drop-In Handguards: These are easier to install and fit into the existing delta ring and front handguard cap. Verify that your barrel has the appropriate hardware for drop-in handguards if this is your choice.

Gas Blocks:

- Low-Profile Gas Blocks: Often used with free-float handguards, low-profile gas blocks provide a sleek profile and are generally more versatile. Ensure your barrel's gas port size and location match the gas block specifications.

- Adjustable Gas Blocks: These allow you to fine-tune the gas flow for different ammunition and suppressors, improving reliability and reducing recoil. Verify compatibility with your barrel’s gas system length (e.g., carbine, mid-length, rifle).

- Compatibility: Ensure the barrel extension matches the upper receiver. Most AR-15 barrels are compatible with standard Mil-Spec upper receivers, but it’s crucial to double-check for any proprietary designs.

- Barrel Nut Compatibility: Verify that the barrel nut provided or required for your handguard system is compatible with the upper receiver threads.

Gas Systems:

- Length Compatibility: Ensure the gas system length of your barrel (carbine, mid-length, rifle) matches the gas tube and handguard length.

- Gas Port Size: Check that the size is appropriate for your intended ammunition and use. This ensures reliable cycling and optimal performance.

Considering these accessories and compatibility factors when choosing your AR-15 barrel will help you build a reliable and efficient rifle tailored to your needs.

Conclusion: Choosing the Perfect AR-15 Barrel

Selecting the right AR-15 barrel involves carefully considering various factors to ensure optimal performance, durability, and compatibility. From understanding the impact of barrel length, profile, and material to making informed decisions about twist rates, gas systems, and chamber specifications, each aspect plays a crucial role in your rifle's overall functionality and accuracy. Additionally, proper installation, maintenance, and compatibility with accessories like muzzle devices and handguards must be considered. By evaluating manufacturing quality, rifling methods, and crown quality, you can further ensure your barrel’s potential for precision. Considering these comprehensive guidelines, you can confidently choose the perfect barrel for your AR-15, tailored to your specific shooting needs and preferences. Taking the time to make an informed decision will enhance your shooting experience and ensure your rifle performs at its best.

Recent Posts

-

Best AR-15 Handguards - MOE SL Handguard

In the world of AR-15 customization, handguards not only protect the barrel but are pivotal in enhan …Feb 5th 2025 -

Budget vs. Premium AR-15 Rifle Scopes: Are Expensive Optics Worth It?

When it comes to enhancing your AR-15's performance, selecting the right AR-15 rifle scope is crucia …Feb 2nd 2025 -

Top Lightweight Red Dot Sights for Minimalist AR-15 Builds

Choosing the right red dot sight for your AR-15 is more than just picking a well-known brand—it’s ab …Jan 30th 2025