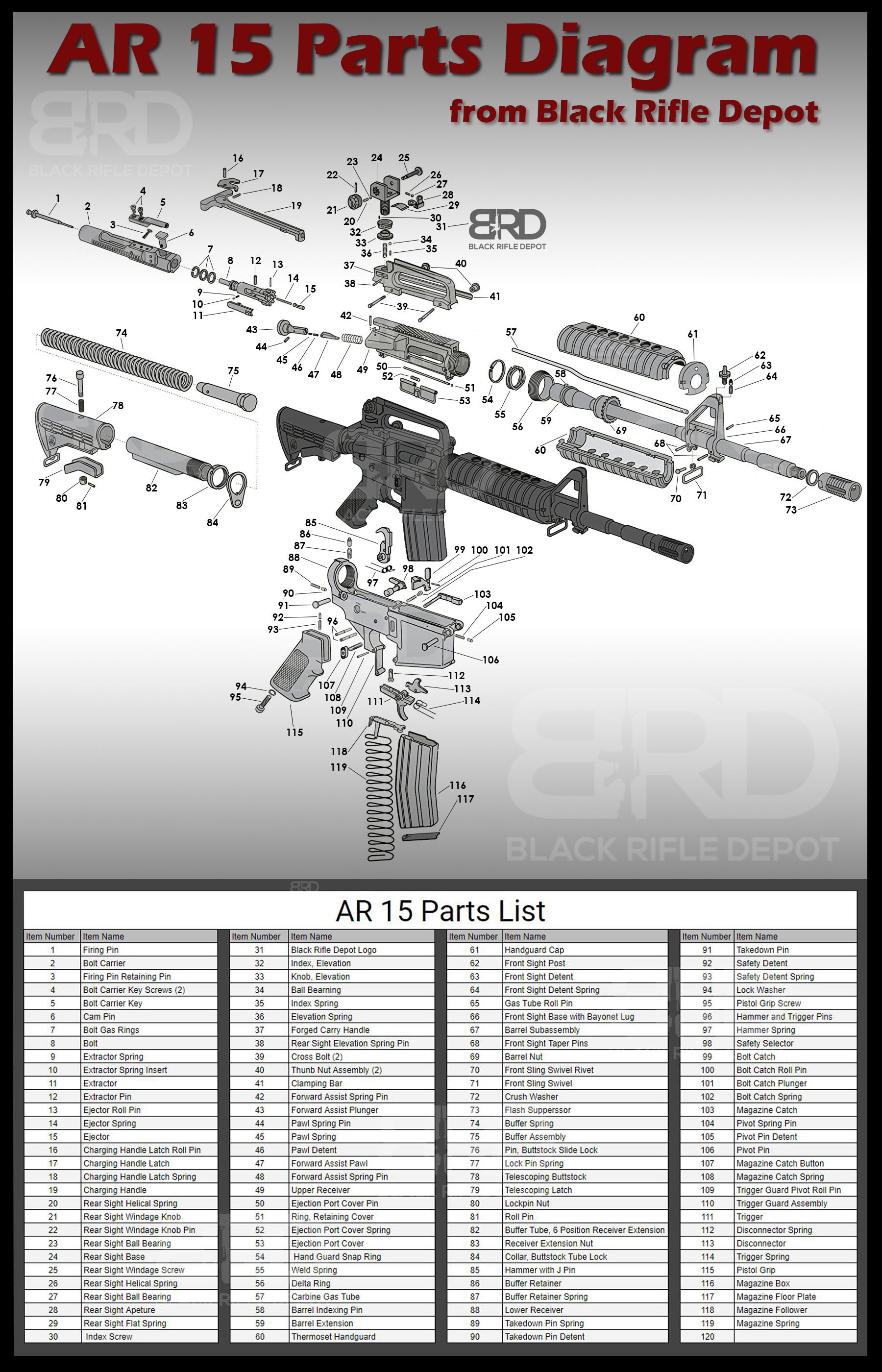

AR 15 Parts Diagram | AR 15 Parts List

The Complete AR 15 Parts Diagram with AR 15 Parts List and all AR 15 Parts Labeled

AR 15 Parts Diagram | AR 15 Parts List

The AR-15 Parts Diagram is an essential visual guide that breaks down the intricate components of this popular rifle platform. It provides a comprehensive understanding of how each part interacts with others to form a functional and reliable firearm. From the upper and lower receivers to the bolt carrier group, gas system, and trigger assembly, the diagram highlights the key elements that make up the AR-15's design. Whether you're a firearm enthusiast, a gunsmith, or a first-time owner, this diagram serves as an invaluable reference, aiding in maintenance, customization, and troubleshooting to ensure optimal performance of your AR-15. For more in-depth information on how to build an AR-15, please check out our other comprehensive guide available on our blog.

1. Firing Pin

The AR-15 firing pin is an essential element in the operation of firearms, serving as the catalyst for the ignition process that discharges a cartridge. This slender, yet crucial component plays a central role in the firing sequence by impacting the cartridge's primer, thus sparking the combustion needed to launch the projectile.

- Material: Firing pins are typically crafted from 8740 hardened steelor stainless, allowing them to endure the impact against the primer without deforming, ensuring longevity and consistent performance.

- Function: Its primary function is to transfer the hammer or striker's force directly to the cartridge's primer, igniting the gunpowder within. This ignition is what propels the bullet or projectile through the barrel and towards the target.

- Role in Operation: In the firearm's firing cycle, the firing pin is indispensable. Without it, the chain reaction required to fire a round cannot commence. The design and proper functioning of the firing pin are critical for the firearm's accuracy, as any inconsistency in the pin's impact can affect the bullet's trajectory.

- Maintenance: Regular maintenance is vital to ensure the firing pin remains functional. It should be inspected routinely for signs of wear, damage, or build-up of residues, which could impede its performance and, consequently, the firearm's reliability.

The design and condition of the firing pin are paramount in ensuring the firearm operates effectively, underscoring the importance of this component in the overall mechanics and safety of the weapon.

-

Mil-Spec Firing Pin: Adheres to military specifications, offering enhanced durability and reliability, essential in combat conditions.

-

Extended Firing Pin: A longer design ensures consistent contact with the primer, especially in modified firearms where standard pins may not provide reliable ignition.

Understanding these aspects underscores the firing pin's significance in firearm functionality and the necessity of proper maintenance to uphold safety and performance.

2. Bolt Carrier

The AR-15 bolt carrier is a pivotal component in many firearms, notably in semi-automatic and automatic rifles, playing an essential role in the firearm's cycling process, which includes ejecting spent cartridges and chambering new rounds.

-

Material: Bolt carriers are typically crafted from robust materials like 158 Carpenter steel, 8620 steel, or 9310 steel, each chosen for its specific properties:

- 158 Carpenter Steel: Known for its exceptional strength and durability, ideal for high-stress components.

- 8620 Steel: Offers good strength and toughness, commonly used in the construction of bolt carrier groups due to its balanced performance.

- 9310 Steel: Superior strength and wear resistance, often used for critical parts that require high durability and resilience.

- Function: The bolt carrier facilitates the movement of the bolt, enabling the extraction of spent cartridges and loading of new ones, which is crucial for the firearm's operation and rapid firing capability.

- Role in Operation: It is central to the efficient cycling of the firearm, ensuring the weapon can fire, eject, and reload smoothly and reliably.

-

Maintenance: Regular maintenance is necessary to keep the bolt carrier in optimal condition. This includes cleaning to remove debris and prevent build-up, as well as inspecting for wear or damage, especially given the high-stress nature of its function.

- Bolt Carrier Body: This is the primary section of the bolt carrier, designed to house and protect the smaller, more intricate components of the bolt carrier group, ensuring cohesive operation.

-

Black Nitride BCG: A favored finish for bolt carriers, black nitride enhances durability, provides excellent corrosion resistance, and reduces friction, which contributes to smoother operation and less need for frequent lubrication.

3. Firing Pin Retaining Pin

The firing pin retaining pin is a small, yet indispensable component in the assembly of many firearms, playing a critical role in securing the firing pin's position within the bolt carrier. This pin is essential for maintaining the correct placement and operational integrity of the firing pin, ensuring the firearm functions as intended.

- Material: Typically crafted from sturdy materials, the firing pin retaining pin is built to withstand the forces exerted during the firing process, ensuring durability and sustained effectiveness.

- Function: Its main function is to hold the firing pin securely within the bolt carrier, preventing any lateral or longitudinal movement that could disrupt the firing pin's alignment or proper function.

- Role in Operation: By maintaining the firing pin's correct positioning, the retaining pin ensures that the firing pin strikes the primer with the necessary precision and force, facilitating the ignition of the cartridge. This precision is crucial for the reliability and safety of the firearm's operation.

- Maintenance: Regular inspection and maintenance of the firing pin retaining pin are essential to ensure its integrity and functionality. Checking for wear, damage, or improper fit is crucial to prevent malfunctions or inconsistencies in the firearm's performance.

The firing pin retaining pin, though small, is vital to the firearm's overall reliability and accuracy, underscoring the importance of each component, no matter the size, in the complex mechanism of a firearm.

4. Bolt Carrier Key Screws

The bolt carrier key screws are essential components within the bolt carrier group (BCG) of many firearms, particularly in gas-operated systems. These screws play a pivotal role in securing the bolt carrier key (also known as the gas key) to the bolt carrier, ensuring that the entire assembly functions cohesively and efficiently.

- Material: Typically made from high-strength steel, bolt carrier key screws are designed to withstand the high pressures and mechanical stresses encountered during the firearm's operation, ensuring durability and reliability.

- Function: Their primary function is to fasten the bolt carrier key firmly to the bolt carrier. The bolt carrier key is a crucial part of the gas-operated system, channeling the gas used to cycle the firearm. The screws ensure that the key remains securely attached to the carrier, preventing gas leaks and ensuring proper cycling of the firearm.

- Role in Operation: In gas-operated firearms, the bolt carrier key interacts directly with the gas system. When a round is fired, gas is funneled through the gas tube and into the bolt carrier key. The secure attachment provided by the screws ensures that this gas is efficiently used to push the bolt carrier, facilitating the extraction and ejection of the spent cartridge and the chambering of a new round. This process is critical for the semi-automatic or automatic operation of the firearm.

- Maintenance: Regular inspection and maintenance of the bolt carrier key screws are crucial. They should be checked for proper torque, signs of wear, or damage. Loose or damaged screws can lead to gas leaks or malfunctions, compromising the firearm's performance and safety.

The bolt carrier key screws are, therefore, integral to the proper function and maintenance of the bolt carrier group in gas-operated firearms, underscoring the importance of every component, no matter how small, in the overall mechanism and reliability of the firearm.

5. Bolt Carrier Key

The bolt carrier key, also known as the gas key, is a critical component in the bolt carrier group (BCG) of gas-operated firearms. It plays an essential role in harnessing the gas pressure to cycle the firearm effectively, connecting the gas system's energy to the firearm's mechanical cycling process.

- Material: The gas key is typically made from 8740 steel, designed to withstand high temperatures and pressures generated by the gas system, ensuring durability and reliability throughout its operational life.

- Function: Its primary function is to channel the hot gas from the fired cartridge, delivered via the gas tube, into the bolt carrier. This gas pressure is what drives the bolt carrier rearward, initiating the extraction and ejection of the spent cartridge case, the re-cocking of the hammer, and the chambering of a new round.

- Role in Operation: The gas key's role is pivotal in the operation of gas-operated firearms. It ensures that the energy generated by the gas system is efficiently transferred to the bolt carrier group, enabling the automated cycling process essential for semi-automatic and automatic firing modes.

- Maintenance: Proper maintenance of the gas key is crucial for the firearm's reliability and safety. This includes ensuring that the gas key is securely attached to the bolt carrier, checking for signs of wear or damage, and ensuring that its internal passage is clean and unobstructed to allow free flow of gas.

The bolt carrier key's functionality is integral to the performance of gas-operated firearms, highlighting its importance in ensuring the effective and reliable operation of the weapon's cycling mechanism.

6. Cam Pin

The cam pin is a crucial element in the bolt carrier group (BCG) of many firearms, especially those with a rotating bolt design, such as in many modern rifles. This component plays a vital role in the mechanical cycling of the firearm, ensuring the correct sequence of locking and unlocking the bolt.

- Material: Typically made from high-strength steel, the cam pin is built to endure the stresses and strains of the firearm's cycling process, ensuring durability and reliability throughout its operational life.

- Function: The cam pin fits through a hole in the bolt and sits within the bolt carrier. Its primary function is to interact with the bolt carrier and the bolt, facilitating the rotational movement necessary for the bolt to lock into the barrel extension or unlock from it. As the bolt carrier moves within the receiver, the cam pin rotates the bolt, engaging or disengaging it with the locking lugs in the barrel extension.

- Role in Operation: During the firing cycle, the cam pin's rotation is essential for the timing and execution of the bolt's locking and unlocking phases. This process is critical for ensuring the firearm's safety and functionality, as it allows the bolt to secure firmly during firing and unlock for the ejection and chambering of rounds.

- Maintenance: Regular inspection and maintenance are crucial for the cam pin's longevity and the firearm's overall reliability. Wear, damage, or improper lubrication can affect its function, potentially leading to malfunctions or increased wear on other components.

The cam pin's efficient operation is integral to the proper function of the firearm's cycling mechanism, highlighting its importance in the overall performance and safety of the weapon. Ensuring that this component is in good working condition is essential for maintaining the firearm's functionality and reliability.

7. Bolt Gas Rings

Bolt gas rings, essential components in gas-operated firearms, play a pivotal role in ensuring the efficient and safe operation of the weapon. These rings are integral to maintaining the necessary seal within the bolt carrier group (BCG), which is crucial for the firearm's cycling process.

- Material: Bolt gas rings are usually made from durable materials capable of withstanding high temperatures and pressures, such as steel or other resilient metal alloys. Their material composition ensures they maintain their sealing properties even under the intense conditions of rapid firing.

- Function: The primary function of bolt gas rings is to seal the space between the bolt and the bolt carrier. This seal is vital for directing the gas energy into moving the BCG to cycle the firearm. When a round is fired, gas is funneled back into the BCG, and the gas rings ensure this gas does not escape, pushing the bolt carrier to the rear and facilitating the extraction and ejection of the spent cartridge, cocking of the hammer, and chambering of a new round.

- Role in Operation: Without effective gas rings, the firearm could fail to cycle correctly, as the necessary gas pressure would not be adequately maintained. The seal created by the gas rings ensures that the gas generated by the fired round is utilized to its full potential, enabling the firearm to function reliably and efficiently.

- Maintenance: Regular inspection and replacement of bolt gas rings are essential for maintaining the firearm's performance. Worn or damaged gas rings can lead to decreased performance and reliability, as they may not maintain the required seal, resulting in failures to cycle properly.

The functionality of bolt gas rings is crucial for the consistent and reliable operation of gas-operated firearms. Their ability to maintain a proper seal within the BCG is fundamental to leveraging the gas energy necessary for the cycling action, underscoring their importance in the overall mechanism of the weapon.

8. Bolt

9. Extractor Spring

The extractor spring is a small but crucial component in the operation of many firearms, playing a vital role in the extraction process during the firearm's cycling operation. This spring ensures the consistent and reliable removal of spent cartridge casings after firing.

- Material: Extractor springs are typically made from high-quality spring steel or similar resilient materials, designed to maintain tension and elasticity through repeated cycles of compression and expansion, ensuring longevity and consistent performance.

- Function: The primary function of the extractor spring is to provide the necessary tension to the extractor, enabling it to grip and retain the rim of the cartridge casing firmly. Upon firing, this tension allows the extractor to pull the spent casing from the chamber and facilitate its ejection from the firearm, making way for the next round to be chambered.

- Role in Operation: In the firearm's cycling process, the extractor spring's role is essential for the smooth and uninterrupted operation of the firearm. It directly influences the reliability of the extraction and ejection phases, which are critical for the firearm's readiness to fire subsequent shots.

- Maintenance: Regular maintenance is vital to ensure the extractor spring's effectiveness and longevity. Inspecting the spring for signs of wear, fatigue, or damage and replacing it when necessary helps maintain the firearm's extraction reliability and overall performance.

The functionality of the extractor spring is crucial for the consistent and reliable operation of the firearm's extraction mechanism, underscoring its importance in the overall cycling process and effectiveness of the firearm.

10. Extractor Spring Insert

The extractor spring insert, a subtle yet significant part of the bolt assembly in many firearms, plays a vital role in the functionality and longevity of the extractor mechanism. Despite its small size, its contribution to the extractor's performance is substantial.

- Material: Typically made from durable materials like polymer, the extractor spring insert is engineered to endure repetitive stress and maintain its structural integrity, ensuring it enhances the extractor mechanism's reliability over time.

- Function: The primary function of the extractor spring insert is to provide consistent support and tension for the extractor spring. It helps in distributing the spring's force more evenly, reducing the likelihood of spring fatigue or failure. This insert ensures that the extractor maintains optimal contact with the cartridge, facilitating reliable extraction of the spent casing.

- Role in Operation: In the bolt assembly, the extractor spring insert is crucial for maintaining the precise tension required for the extractor to function effectively. By enhancing the spring's performance, the insert ensures that the extractor mechanism operates smoothly, contributing to the firearm's overall reliability, particularly during the critical phases of extraction and ejection.

- Maintenance: While the extractor spring insert is designed for durability, regular inspection is recommended to ensure it remains in good condition and functions as intended. Checking for wear, deformation, or damage is essential to maintaining the extractor mechanism's efficiency and the firearm's operational reliability.

The extractor spring insert, though small, is instrumental in optimizing the extractor's performance, highlighting its importance in the effective and reliable operation of the firearm's bolt assembly.

11. Extractor

The extractor is a vital element in the bolt assembly of firearms, especially significant in semi-automatic and automatic weapons. It's a key player in the firearm's cycling process, ensuring the smooth and reliable transition through the various phases of operation.

- Material: Extractors are typically made from high-strength steel or similar durable materials, designed to withstand the stress of constant use and to effectively grip and extract cartridge casings without wearing down or failing.

- Function: The primary role of the extractor is to hook onto the rim of the cartridge casing after a round is fired, pulling the spent casing out of the chamber as the bolt moves rearward. This action is crucial for clearing the chamber to allow a new cartridge to be loaded, facilitating continuous firing.

- Role in Operation: In the operation cycle of a firearm, the extractor's role is central to the extraction phase, which is integral to the overall cycling process. A reliable extractor ensures that spent casings are consistently and efficiently removed from the chamber, preventing malfunctions that could impede the firearm's operation.

- Maintenance: Regular maintenance is essential for the extractor, ensuring it remains in good working condition. Inspecting the extractor for wear, ensuring it maintains proper tension, and cleaning it to remove any built-up residue are all crucial steps in preserving its functionality and, by extension, the reliability of the firearm.

The extractor's functionality is critical for the firearm's ability to perform its basic operations of feeding, firing, and ejecting cartridges, underscoring its importance in the mechanics of semi-automatic and automatic weapons. Ensuring its reliability is paramount for the overall performance and safety of the firearm.

12. Extractor Pin

The Charging Handle Latch Roll Pin is an essential component in the functionality of firearms that are equipped with charging handles. This small but vital piece plays a significant role in the mechanical operation of the firearm, ensuring the charging handle operates smoothly and efficiently.

- Material: Typically crafted from high-strength steel or similar durable materials, the Charging Handle Latch Roll Pin is designed to endure the wear and tear of regular use, maintaining its shape and structural integrity to provide consistent performance throughout its lifespan.

- Function: The primary role of this pin is to secure the charging handle latch in place, allowing it to pivot as needed. This pivotal action is crucial for the charging handle's operation, enabling the user to cock the firearm and prepare it for firing or clearing malfunctions.

- Role in Operation: In the overall mechanism of the firearm, the Charging Handle Latch Roll Pin is fundamental to ensuring that the charging handle functions correctly. It ensures the latch is securely attached and able to move as required, which is vital for the firearm's operation, whether for loading, clearing a jam, or performing maintenance.

- Maintenance: Regular inspection and maintenance are key to ensuring the Charging Handle Latch Roll Pin remains in optimal condition. Checking for wear, ensuring it's properly seated, and replacing it if necessary are important steps in maintaining the firearm's functionality and user safety.

The Charging Handle Latch Roll Pin, while small, is a testament to the precision engineering involved in firearm design, demonstrating how even the smallest components are crucial for the reliable and safe operation of the weapon.

13. Ejector Roll Pin

The ejector roll pin is a critical component within the bolt mechanism of a firearm, serving as a retaining pin that ensures the ejector remains correctly positioned for the firearm's optimal operation. This pin is instrumental in keeping the ejector securely in place, enabling it to perform its vital function during the firearm's cycling process.

- Material: Constructed from durable materials, typically high-strength steel, the ejector roll pin is designed to endure the stresses and strains associated with the rapid movements and forces within the bolt mechanism, ensuring long-term reliability and stability.

- Function: The primary role of the ejector roll pin is to secure the ejector within the bolt assembly. The ejector, under the tension of its spring, plays a crucial role in contacting and expelling spent cartridges from the firearm. The pin ensures that the ejector is precisely positioned to apply the necessary force to eject the casing efficiently after each shot.

- Role in Operation: In the firearm's operational cycle, the ejector roll pin is vital for the consistent performance of the ejection process. By maintaining the ejector's correct alignment and position, the pin ensures that spent cartridges are reliably ejected, facilitating smooth and uninterrupted operation, which is essential for the firearm's readiness for the next action.

- Maintenance: Proper maintenance of the ejector roll pin is essential for the firearm's overall performance and reliability. Regular inspection for wear, proper seating, and potential deformation is crucial to prevent malfunctions that could arise from a compromised ejector function.

The ejector roll pin, while small and unassuming, plays a crucial role in the mechanical efficiency and operational reliability of a firearm, underscoring the importance of every component, no matter the size, in the intricate mechanism of firearms.

14. Ejector Spring

The ejector spring is a small yet essential part of a firearm's firing mechanism, playing a vital role in the ejection of spent cartridges. It operates in tandem with the extractor, providing the necessary force to expel spent rounds from the firearm. This action is critical for the rapid clearing of the chamber, facilitating quick reloading and ensuring the continuity of the firing cycle. The reliability of the ejector spring directly influences the firearm's ability to avoid jams and maintain consistent firing.

- Material: Constructed from high-tensile strength materials, the ejector spring is designed to withstand the demands of repeated compressions and expansions, maintaining its structural integrity over time.

- Function: The primary role of the ejector spring is to supply the force required to propel spent cartridges from the firearm, a key factor in the weapon's ability to function smoothly and efficiently.

- Role in Cycling: The ejector spring is critical in the ejection phase of the firearm's operation, playing a central role in ensuring that the chamber is cleared quickly, allowing for the next round to be chambered without delay.

- Maintenance: Regular checks are crucial for the ejector spring to ensure it retains its tension and structural integrity, which are essential for consistent and effective performance.

Understanding the importance of the ejector spring and maintaining it properly are vital for the optimal functioning of a firearm, emphasizing the significance of each component, no matter how small, in the overall mechanism of the weapon.

15. Ejector

The ejector is a crucial component in the operation of semi-automatic and automatic firearms, playing a key role in the ejection process. It works in concert with the ejector spring, applying the necessary force to remove spent casings from the firearm. This process begins when a round is fired and the extractor holds the spent casing. The firearm's action compresses the ejector spring, and upon release, the ejector hits the base of the casing at a precise point, leveraging the spring's energy to eject the casing through the port. This efficient ejection is vital for the firearm's ability to perform rapid, reliable firing, ensuring seamless reloading and a consistent firing sequence.

- Material: The ejector is made from robust materials, enabling it to endure the significant forces and impacts encountered during the ejection of casings.

- Function: It employs the energy from the ejector spring to forcefully remove spent casings from the firearm, an essential action for the weapon's efficient reloading and continuous firing capabilities.

- Role in Cycling: The ejector is integral to the ejection phase of the firearm's operation cycle, playing a pivotal role in clearing the chamber quickly and preparing the weapon for the subsequent round, thus contributing to the firearm's speed and reliability in firing.

- Maintenance: Regular inspections are necessary to ensure the ejector continues to function correctly and effectively, helping to prevent any ejection issues that could interrupt the firearm's operation.

Understanding and maintaining the ejector's condition is crucial for the consistent performance and reliability of semi-automatic and automatic firearms, highlighting the importance of each component in the overall functionality of the weapon.

16. Charging Handle Latch Roll Pin

The Charging Handle Latch Roll Pin is a critical component in firearms that feature charging handles, playing a pivotal role in their functionality. This small pin has a dual purpose: it secures the latch to the charging handle and acts as a pivot point for the latch's movement, both of which are crucial for the smooth operation of the charging handle. This, in turn, is essential for efficiently cocking the firearm and ensuring it is ready for use. Despite its small size, the pin's function is significant in maintaining the firearm's reliability and performance.

- Material: The pin is crafted from durable materials, designed to withstand the rigors of repeated use and maintain its integrity over time, ensuring the longevity of the charging handle mechanism.

- Function: It serves to anchor the latch securely to the handle, providing a pivot point that allows for the latch's necessary movement. This function is crucial for the smooth and effective operation of the charging handle, enabling the user to cock the firearm efficiently.

- Role in Operation: The pin is vital for the correct functioning of the charging handle, a key component in preparing the firearm for action. Its proper operation is essential for the firearm's readiness and overall performance.

- Maintenance: Regular maintenance is required to ensure the pin is not worn or loose, which is essential for preserving the firearm's operational integrity. Regular checks help prevent potential malfunctions and ensure the charging handle operates as intended.

Maintaining the Charging Handle Latch Roll Pin in optimal condition is crucial for the effective and reliable operation of firearms with charging handles, highlighting the importance of even the smallest components in the overall functionality of the weapon.

17. Charging Handle Latch

The Charging Handle Latch is a pivotal element in firearms, particularly in those with an independent charging handle. Its main role is to release the charging handle from the receiver, enabling the handle to be retracted. This retraction is a vital action for cocking the firearm or clearing it. The latch guarantees that this operation is both secure and straightforward, offering a dependable method for users to engage the charging handle as needed. Its design and operational efficiency are crucial for the firearm's effective and safe use.

- Material: Crafted from 7075-T6 aluminum to withstand regular engagement and ensure durability.

- Function: Allows the disengagement of the charging handle from the receiver, facilitating essential actions like cocking or clearing the firearm.

- Role in Operation: Ensures the secure and smooth operation of the charging handle, critical for the firearm's readiness and safety.

- Maintenance: Regular checks are necessary to ensure its proper function and structural integrity, maintaining the firearm's overall performance and safety.

18. Charging Handle Latch Spring

The charging handle latch spring is a crucial component in firearms, providing the necessary tension to keep the charging handle latch in place during use. This spring plays a vital role in the manual operation of the bolt or bolt carrier, which is essential for the firearm's safe and efficient functioning. The integrity and performance of this spring are directly linked to the reliability of the charging handle, ensuring it remains securely positioned throughout the firearm's operation.

- Material: Constructed from high-quality spring steel to maintain consistent tension and durability.

- Function: Delivers the required tension to the latch, securing the charging handle in the correct position for reliable operation.

- Role in Operation: Essential for the smooth and secure manual operation of the charging handle, affecting the firearm's safety and efficiency.

- Maintenance: Needs periodic inspection to ensure it maintains its tension and integrity, preventing operational failures.

19. Charging Handle

The AR-15 charging handle is the central element of the charging handle assembly in a firearm, acting as the core structure around which the assembly is constructed. Its function is to enable the manual manipulation of the firearm's bolt or bolt carrier, which is key for cocking the weapon, addressing malfunctions, or preparing it to fire. The design and user-friendliness of the charging handle are vital for the effective and safe use of the firearm, offering the shooter a dependable method to manually operate the firearm's action.

- Material: Made from s7075-T6 aluminum alloy to withstand the rigors of repeated use and provide a long service life.

- Function: Allows for the manual engagement and operation of the bolt or bolt carrier, essential for chambering a round, clearing jams, or preparing it for use.

- Role in Operation: Central to the user's ability to interact with the firearm's mechanical action, influencing the ease and safety of operation.

- Maintenance: Requires regular inspection and cleaning to ensure it operates smoothly and maintains its structural integrity.

20. Rear Sight Helical Spring

The rear sight helical spring is an essential part of a firearm's sighting system, designed to apply steady tension on the sight bearing located in the windage adjustment knob. This spring is crucial for maintaining the rear sight's precise and stable positioning, enabling shooters to adjust and align the sight accurately for precise targeting. Its helical structure is crafted for endurance and consistent performance, ensuring the sight's alignment remains intact through numerous recoils and adjustments, thus preserving the firearm's long-term accuracy.

- Material: Constructed from resilient materials to ensure it can withstand the forces of adjustment and recoil while maintaining its shape and tension.

- Function: Provides the necessary tension to the sight bearing, aiding in precise and stable windage adjustments of the rear sight.

- Role in Operation: Key to the accurate and reliable adjustment of the rear sight, contributing to the overall aiming and shooting accuracy of the firearm.

- Maintenance: Needs regular inspection to ensure it remains in good condition and functions correctly, preserving the firearm's accuracy.

21. Rear Sight Windage Knob

The rear sight windage knob is a crucial component of a firearm's aiming system, specifically crafted to allow for precise lateral adjustments of the rear sight. This knob facilitates the shooter's ability to make fine-tuned adjustments to the sight's alignment, counteracting the effects of windage, or the horizontal deviation in the bullet's path caused by crosswinds. Through the manipulation of the windage knob, shooters can refine their aim, significantly improving the firearm's accuracy and performance. This adjustment capability is essential for maintaining optimal aiming precision, especially when shooting over long distances or in changing wind conditions.

- Material: Made from robust materials to endure frequent adjustments and maintain its functional integrity.

- Function: Enables precise lateral adjustments of the rear sight to correct for horizontal discrepancies in the bullet's trajectory.

- Role in Operation: Vital for fine-tuning the firearm's aim, allowing shooters to compensate for windage and enhance accuracy.

- Maintenance: Requires consistent monitoring and maintenance to ensure it remains accurate and responsive to adjustments.

22. Rear Sight Windage Knob Pin

The Rear Sight Windage Knob Pin plays a pivotal role in a firearm's rear sight assembly, serving as the connecting element that secures the windage knob to the windage screw. This pin is essential for ensuring that rotations of the windage knob are accurately conveyed to the sight aperture, facilitating its movement to the left or right as needed. Such a mechanism is crucial for the precise lateral adjustments of the sight, allowing shooters to fine-tune the firearm's alignment for windage compensation or accurate target acquisition. The absence of this pin would disrupt the transfer of adjustments from the knob to the sight, significantly affecting the firearm's aiming precision.

- Material: Constructed from durable material to ensure secure attachment and enduring functionality.

- Function: Links the windage knob to the windage screw, enabling accurate translation of adjustments to the sight aperture.

- Role in Operation: Fundamental for the accurate lateral adjustment of the rear sight, critical for precise aiming and accuracy enhancement.

- Maintenance: Regular inspection is necessary to ensure it remains securely in place and functions correctly, maintaining the firearm's accuracy.

23. Rear Sight Ball Bearing

The Rear Sight Ball Bearing is an integral part of the rear sight mechanism on a firearm, playing a key role in its functionality. This small but crucial component is designed to exert consistent tension on the windage knob, ensuring that once the knob is adjusted to the desired setting, it remains securely in place. This stability is vital for preventing any unwanted movement that could impact the firearm's aiming accuracy.

- Material: The ball bearing is constructed from high-quality materials that are chosen for their durability and ability to withstand the demands of repeated use, thereby ensuring the longevity of the rear sight mechanism.

- Function: Its primary function is to maintain steady tension on the windage knob, which is essential for keeping the knob—and thus the sight—fixed in the chosen position. This ensures that the adjustments made to the sight remain unchanged, preserving the accuracy of the firearm over time and under various conditions.

- Role in Operation: The Rear Sight Ball Bearing is crucial for the precise operation of the rear sight, enabling shooters to make reliable and stable adjustments to their aim. Its effectiveness directly influences the consistency and reliability of the firearm's accuracy.

- Maintenance: To ensure its continued performance and reliability, regular maintenance of the ball bearing is essential. This includes checking for wear and ensuring that it remains in good condition, as any degradation could affect the rear sight's stability and the firearm's overall accuracy.

By maintaining the Rear Sight Ball Bearing in optimal condition, shooters can trust in the stability and reliability of their firearm's rear sight adjustments, which is crucial for accurate and consistent shooting.

24. Rear Sight Base

The Rear Sight Base is an essential component of a firearm's rear sight assembly, acting as the cornerstone upon which the entire rear sight structure is built. This base provides a solid and stable platform, anchoring all other components of the rear sight and ensuring their proper interaction and function. Its role is fundamental in preserving the structural integrity and operational efficacy of the sighting system.

- Material: The base is typically made from robust materials that offer strength and durability, ensuring it can support the rear sight assembly and withstand the rigors of firearm operation.

- Function: The primary function of the Rear Sight Base is to offer a secure mount for the rear sight, ensuring that all components are correctly aligned and affixed, which is crucial for the sight's accuracy and stability.

- Role in Operation: It plays a critical role in the firearm's aiming system, maintaining the alignment and accuracy of the rear sight. The base's stability directly influences the firearm's effectiveness and reliability in aiming and shooting.

- Maintenance: Ensuring the Rear Sight Base is in good condition and securely attached is vital for the firearm's accuracy. Regular checks and maintenance are required to keep the base in optimal condition, thus maintaining the overall integrity and functionality of the sighting system.

The Rear Sight Base's condition and stability are paramount for the proper function and accuracy of a firearm's rear sight, underscoring its significance in the effective operation of the firearm's aiming system.

25. Rear Sight Windage Screw

The Rear Sight Windage Screw is a crucial element in the sighting apparatus of a firearm, linking directly with the windage knob to facilitate precise adjustments. This screw is instrumental in enabling the lateral movement of the sight's aperture, allowing shooters to make meticulous adjustments for accurate aiming.

- Material: Crafted from durable materials, the windage screw is designed to withstand the rigors of adjustments, ensuring longevity and consistent performance.

- Function: It allows the windage knob to alter the position of the sight's aperture, providing the shooter with the capability to make precise lateral adjustments for optimal aiming accuracy.

- Role in Operation: The windage screw is vital for adjusting the firearm's sight for windage corrections, enabling shooters to achieve precise aim and accuracy in various shooting conditions.

- Maintenance: Regular maintenance is necessary to ensure the windage screw functions smoothly, allowing for consistent and reliable sight adjustments.

The functionality of the Rear Sight Windage Screw is essential for the accurate adjustment of the firearm's sights, playing a key role in the shooter's ability to achieve precise aim and accuracy, especially when compensating for windage.

26. Rear Sight Helical Spring

The Rear Sight Ball Bearing is a key component in a firearm's sighting system, integral to maintaining consistent tension and ensuring the stability of the sight mechanism. This small but essential part plays a pivotal role in the smooth operation of the sight adjustments.

- Material: Made from high-quality materials that are selected for their durability and ability to withstand friction and wear, ensuring the ball bearing remains effective over time.

- Function: The ball bearing works in conjunction with the helical spring and windage adjustments to facilitate smooth and precise changes to the sight's position. It is crucial for keeping the sight stable and in the set position, preventing any inadvertent shifts that could impact aiming accuracy.

- Role in Operation: It is essential for the precision and reliability of the sighting system, enabling the shooter to make accurate and consistent adjustments. The ball bearing's stability ensures that once the sight is adjusted, it remains in place, even during recoil or handling.

- Maintenance: Regular maintenance is necessary to ensure the ball bearing remains in good condition and continues to function as intended, contributing to the overall effectiveness and accuracy of the firearm's sighting system.

The Rear Sight Ball Bearing's contribution to the sighting system is fundamental, as it directly affects the shooter's ability to aim accurately and consistently, highlighting its importance in the effective operation of the firearm.

28. Rear Sight Aperture

The Rear Sight Aperture is a vital element in a firearm's sighting system, serving as the focal point for the shooter to align the gun's aim accurately with the target. This component, a small hole or notch at the rear sight, works in conjunction with the front sight to facilitate precise targeting.

- Material: Crafted from robust materials, the aperture is designed to endure the rigors of regular use while maintaining its structural integrity, ensuring reliable performance over time.

- Function: The aperture's primary role is to enhance the shooter's focus and vision alignment, allowing for a clear and precise sight picture when aiming. It narrows the field of view, directing the shooter's focus to align the front and rear sights with the target effectively.

- Role in Operation: It is crucial for the accuracy and effectiveness of the firearm's aiming process. By providing a defined point of reference, the rear sight aperture greatly influences the shooter's ability to align the firearm accurately with the intended point of impact.

- Maintenance: Keeping the rear sight aperture clean and clear of obstructions is essential for optimal functionality. Regular checks ensure that the aperture remains in good condition, free from wear or damage that could impede the shooter's vision or the sighting accuracy.

The Rear Sight Aperture's design and condition are fundamental to the shooter's ability to acquire a clear and accurate sight picture, underscoring its importance in the precision and overall performance of the firearm's sighting system.

29. Rear Sight Flat Spring

The Rear Sight Flat Spring is an indispensable element in the rear sight assembly of a firearm, playing a key role in ensuring the stability and adjustability of the aperture. This spring exerts continuous pressure on the aperture, a feature that is essential for maintaining the accuracy of the firearm's aiming system.

- Material: Constructed from durable, flexible materials, the flat spring is engineered to provide consistent tension while withstanding the stresses of adjustment and use, ensuring long-term reliability.

- Function: Its primary function is to maintain consistent pressure on the aperture, securing it in place to prevent any movement that could affect aiming accuracy. The spring also allows for the aperture to be adjusted, either flipped forward or backward, to accommodate different sighting needs.

- Role in Operation: The flat spring is crucial for the aperture's stability and adjustability, directly impacting the shooter's ability to aim accurately. By enabling the selection of different aperture sizes, it allows shooters to adapt their sighting based on varying conditions or preferences, enhancing the firearm's versatility.

- Maintenance: Regular inspection and maintenance are essential to ensure the flat spring maintains its tension and functionality. Proper care prevents the spring from becoming loose or damaged, which could compromise the rear sight's accuracy and the firearm's overall performance.

The functionality and condition of the Rear Sight Flat Spring are vital for the precision and adaptability of the rear sight assembly, highlighting its significance in the effective operation and accuracy of the firearm.

30. Index Screw

The Index Screw is a crucial element in the sighting system of a firearm, designed to anchor the sight securely, ensuring it is correctly oriented and aligned with the firearm's barrel. This small but vital component ensures that the sight maintains its proper position, directly impacting the shooter's ability to aim accurately.

- Material: Made from durable materials, the index screw is built to withstand the mechanical stresses involved in firing and adjusting the firearm, ensuring it remains securely in place over time.

- Function: Its primary role is to lock the sight into the correct orientation, preventing any deviation that could affect the alignment with the barrel. This secure positioning is essential for maintaining the sight's alignment, thereby ensuring that the firearm's point of aim is consistent with the point of impact.

- Role in Operation: The index screw is integral to the sighting system's precision. By securing the sight in the correct orientation, it plays a central role in the firearm's accuracy, directly affecting the shooter's ability to hit the intended target.

- Maintenance: Regular checks and maintenance are essential to ensure the index screw remains tight and effective. Any loosening could lead to misalignment and a decrease in shooting accuracy, underscoring the importance of this component in the firearm's overall performance.

The Index Screw's functionality is pivotal in maintaining the firearm's sighting accuracy, emphasizing its significance in the successful operation and effectiveness of the firearm's alignment system.

31. Black Rifle Depot Logo

The Black Rifle Depot logo signifies excellence in AR products, symbolizing a commitment to quality, value, and customer satisfaction. It assures consumers of premium AR components, backed by exceptional service and quick delivery, reflecting the brand's reputation for reliability and fair pricing.

32. Index, Elevation

The Index Elevation is an integral component of the sight post on a firearm, designed to facilitate the adjustment of the sight's vertical alignment. This feature is vital for shooters aiming to achieve precise shot placement over different distances, allowing for meticulous elevation adjustments.

- Material: Constructed from robust materials, the Index Elevation is engineered to withstand adjustments and maintain its position, ensuring long-lasting reliability and precision.

- Function: It enables the shooter to adjust the elevation of the sight, allowing for fine-tuning of the vertical alignment. This adjustment is critical for compensating for bullet drop over various distances, ensuring the aim is accurately aligned with the target's elevation.

- Role in Operation: The Index Elevation plays a crucial role in the accuracy of the firearm, particularly over longer ranges where elevation adjustments are necessary to ensure the point of aim meets the point of impact.

- Maintenance: To maintain its functionality and accuracy, the Index Elevation should be regularly checked and maintained, ensuring it remains in optimal condition for precise adjustments.

By effectively utilizing the Index Elevation, shooters can enhance their firearm's accuracy, adapting to different shooting distances and conditions, thereby achieving consistent shot placement.

33. Knob, Elevation

The Elevation Knob is a fundamental element of a firearm's sighting system, enabling the shooter to adjust the sight's vertical axis. This knob is instrumental in ensuring the accuracy of the firearm, allowing users to adapt the sight's elevation for optimal shot placement across varying ranges.

- Material: Crafted from sturdy materials, the Elevation Knob is designed to endure frequent adjustments and maintain its effectiveness, ensuring reliable performance under different conditions.

- Function: It provides the shooter with the ability to fine-tune the vertical positioning of the sight, a critical feature for achieving precise aim. This functionality is key to adjusting for bullet drop, which varies with distance, ensuring the sight aligns with the intended target's elevation.

- Role in Operation: The Elevation Knob is vital for the firearm's accuracy, particularly at longer ranges where elevation adjustments are necessary for accurate targeting. It enables shooters to make necessary corrections based on the distance to the target, enhancing the firearm's effectiveness.

- Maintenance: Regular maintenance is essential to keep the Elevation Knob functioning smoothly. It should be checked periodically to ensure it remains in good working order, allowing for precise and reliable adjustments.

Utilizing the Elevation Knob effectively allows shooters to enhance their firearm's accuracy, adapting to various distances and ensuring consistent and accurate shot placement in diverse shooting environments.

34. Ball Bearing

The Ball Bearing in a firearm's rear sight mechanism plays a pivotal role in the elevation adjustment system, ensuring the stability and accuracy of the sight settings. This small component is integral to maintaining the correct elevation position, contributing significantly to the firearm's aiming precision.

- Material: Made from high-quality, durable materials, the ball bearing is designed to endure the stresses of use while providing consistent tension, ensuring its longevity and reliability in the sight mechanism.

- Function: Its primary role is to apply consistent tension to the elevation post, a key aspect of maintaining the set elevation angle. This tension prevents any unwanted movement or shift in the elevation setting, critical for precise aiming and shot accuracy.

- Role in Operation: The ball bearing is essential for securing the elevation adjustments, ensuring that the rear sight's elevation remains fixed during firing or handling. This stability is crucial for accurate shot placement, especially at varying distances.

- Maintenance: Regular maintenance is necessary to ensure the ball bearing continues to function effectively. It should be checked for wear or damage and kept clean to prevent any issues that could affect the rear sight's accuracy.

Incorporating the Ball Bearing into the rear sight mechanism enhances the firearm's overall accuracy by providing stable and precise elevation adjustments, crucial for consistent aiming and effective shot placement.

35. Index Spring

The Index Spring is an essential element in the rear sight assembly of a firearm, specifically functioning within the elevation index section to apply necessary pressure on the ball bearing. This component plays a key role in the accuracy and stability of the firearm's elevation adjustments.

- Material: Constructed from durable and resilient materials, the Index Spring is designed to provide consistent pressure over an extended period, ensuring its reliability and longevity within the sight mechanism.

- Function: Its principal role is to ensure that the ball bearing exerts uniform tension, a crucial aspect for maintaining the elevation adjustments' stability. This consistent pressure ensures that the elevation settings remain fixed and do not shift during use, which is essential for accurate aiming.

- Role in Operation: The Index Spring is central to the effective functioning of the elevation adjustment mechanism. By providing the necessary tension, it allows shooters to make precise and dependable adjustments to the sight's elevation, essential for accurate targeting across various distances.

- Maintenance: To ensure ongoing reliability and effectiveness, the Index Spring requires regular maintenance. It should be checked for signs of wear or fatigue and kept clean to prevent any potential malfunction, which could impact the firearm's accuracy.

The Index Spring's contribution to the rear sight assembly is crucial for the precision and reliability of a firearm's elevation adjustments, underscoring its importance in the overall aiming and shooting accuracy of the firearm.

36. Elevation Spring

The Elevation Spring is a significant component within the rear sight assembly of a firearm, integral to the maintenance and stability of the elevation settings. This larger spring ensures that the elevation component remains fixed in its desired position, crucial for the accuracy and reliability of the firearm's sighting system.

- Material: Constructed from robust materials, the Elevation Spring is designed to endure the demands of regular adjustments and recoil, ensuring durability and consistent performance.

- Function: Its primary function is to provide the necessary tension to keep the elevation component of the rear sight in a stable position. This stability is vital to prevent any accidental shifts that could impact the firearm's aiming precision.

- Role in Operation: The Elevation Spring is central to the rear sight's functionality, particularly in the elevation adjustment mechanism. It ensures that the adjustments made to the sight's elevation are maintained and remain consistent, allowing for precise and dependable aiming adjustments.

- Maintenance: Regular maintenance is crucial for the Elevation Spring to ensure its continued effectiveness. It should be inspected for signs of wear or damage and kept clean to maintain the rear sight's accuracy and functionality.

The Elevation Spring's role in the rear sight assembly is indispensable for the consistent and accurate adjustment of the firearm's elevation settings, highlighting its importance in the overall effectiveness and reliability of the sighting system.

37. Forged Carry Handle

The AR-15 Forged Carry Handle is a key structural component of the carry handle rear sight assembly on a firearm, known for its enhanced strength and durability due to the forging process. This component serves dual purposes: as a physical handle for carrying the firearm and as an integrated part of the sighting system.

- Material: The handle is made through a forging process, which involves shaping metal under high pressure and temperature. This method significantly enhances its strength, durability, and resistance to wear, making it a reliable component for frequent use.

- Function: Beyond serving as a convenient handle for carrying the firearm, it also houses the rear sight assembly, playing a pivotal role in the firearm's aiming mechanism. The design ensures that the rear sight is securely mounted, providing a stable and consistent platform for accurate sighting.

- Role in Operation: The Forged Carry Handle is integral to the firearm's overall functionality, offering a robust structure that contributes to the steadiness and reliability of the sighting system. Its sturdy design aids in maintaining the alignment of the rear sight, essential for precise aiming and shooting.

- Maintenance: While the forged construction ensures longevity, regular maintenance is still necessary to keep the carry handle in optimal condition. This includes checking for any signs of wear or damage and ensuring that the rear sight remains securely attached and aligned.

The Forged Carry Handle's robust construction and dual functionality underscore its importance in enhancing the firearm's usability and reliability, especially concerning accurate sighting and ease of handling.

38. Rear Sight Elevation Spring Pin

The Rear Sight Elevation Spring Pin is an essential element within the rear sight assembly of a firearm, playing a pivotal role in anchoring the elevation spring. This pin is fundamental in preserving the correct positioning and functionality of the spring, which is crucial for the rear sight's elevation adjustment accuracy.

- Material: Crafted from durable materials, this pin is designed to withstand the forces exerted by the elevation spring and the operational stresses of the firearm, ensuring it maintains its structural integrity and function over time.

- Function: Its main purpose is to securely fasten the elevation spring in place, preventing any movement that could lead to inconsistency or loss of tension. This stability is vital for the precise adjustment and functioning of the rear sight's elevation mechanism.

- Role in Operation: The Elevation Spring Pin is crucial for the rear sight's accuracy and reliability. By securing the elevation spring, it ensures that the rear sight maintains its set elevation, allowing for consistent and reliable aim adjustments.

- Maintenance: Regular inspection and maintenance are necessary to ensure that the pin is not worn or damaged, which could affect the stability and effectiveness of the elevation spring and, consequently, the accuracy of the rear sight.

The Rear Sight Elevation Spring Pin's role is indispensable in the firearm's sighting mechanism, ensuring the elevation adjustments are stable and reliable, thus contributing significantly to the overall accuracy and dependability of the firearm.

39. Cross Bolt (2)

The Cross Bolts are essential elements in the assembly of a firearm, particularly in attaching the carry handle rear sight assembly to the firearm's upper receiver via the picatinny rail. These bolts are key in ensuring that the sight assembly is securely fastened and remains consistently stable during the operation of the firearm.

- Material: Constructed from robust materials, the Cross Bolts are designed to endure the stresses and vibrations of firing, maintaining their grip and preventing loosening over time to ensure long-lasting reliability.

- Function: The primary function of these bolts is to secure the carry handle rear sight assembly firmly to the picatinny rail, providing a stable platform for the sighting system. This firm attachment is crucial for preventing any movement or misalignment of the rear sight, which is essential for accurate aiming.

- Role in Operation: The Cross Bolts are vital for the stability and alignment of the rear sight assembly. Their ability to keep the assembly locked in place directly impacts the firearm's accuracy and the shooter's confidence in consistent aim and shot placement.

- Maintenance: Regular checks are necessary to ensure the Cross Bolts remain tight and secure. Any loosening could lead to a shift in the rear sight assembly, affecting the firearm's accuracy. Proper maintenance includes ensuring the bolts are not corroded, damaged, and are adequately torqued to the manufacturer's specifications.

The Cross Bolts' functionality and condition are critical for the overall performance and reliability of the firearm's sighting system, highlighting their importance in the precision and dependability of the shooter's aim.

40. Thumb Nut Assembly

The Thumb Nut Assembly, comprising two thumb nuts, plays a crucial role in the user-friendly attachment and detachment of the rear sight or handle assembly on a firearm. This assembly is specifically designed to enable the easy and efficient tightening or loosening of the cross bolts, facilitating the swift installation or removal of the sight/handle without the necessity for tools.

- Material: These thumb nuts are crafted from durable materials, ensuring they can withstand repeated use and provide reliable performance in securing the assembly to the firearm.

- Function: The main function of the thumb nut assembly is to provide a convenient and efficient means of adjusting the tightness of the cross bolts. This allows for quick and tool-free installation or removal of the rear sight/handle assembly, enhancing the firearm's adaptability in various situations.

- Role in Operation: The thumb nuts are instrumental in securing the rear sight/handle assembly firmly to the firearm, ensuring it remains stable and accurate during use. Their design allows for quick adjustments, enabling shooters to easily modify their firearm's configuration in response to different operational requirements or preferences.

- Maintenance: While the thumb nuts are designed for ease of use, regular checks are recommended to ensure they remain in good condition and function correctly. This includes ensuring they are not stripped, corroded, or damaged, which could affect their ability to secure the assembly effectively.

The Thumb Nut Assembly's contribution to the functionality and versatility of the firearm's sighting system underscores its importance, providing a secure yet easily adjustable mechanism that caters to the dynamic needs of the user.

41. Clamping bar

The Clamping Bar is an essential component in the rear sight/handle assembly of a firearm, acting as a key tension element that ensures the assembly's secure attachment to the firearm. This bar works in conjunction with thumb nuts and cross bolts to maintain a firm and stable connection to the Picatinny rail or other mounting systems.

- Material: Made from strong, durable materials, the clamping bar is designed to withstand significant pressure and maintain its structural integrity over time, ensuring reliable performance and longevity.

- Function: Its primary function is to apply consistent and even pressure at the connection point between the rear sight/handle assembly and the firearm's mounting rail. This pressure is crucial for preventing any movement or loosening that could compromise the sighting system's stability.

- Role in Operation: By ensuring that the rear sight/handle assembly remains securely fastened to the firearm, the clamping bar plays a critical role in the overall stability and accuracy of the sighting system. It prevents shifts or vibrations that could affect aim and shot precision.

- Maintenance: Regular inspection and maintenance are vital to ensure the clamping bar remains effective. This includes checking for signs of wear, ensuring it is not bent or damaged, and confirming that it applies even pressure to maintain the assembly's secure attachment.

The Clamping Bar's role is pivotal in maintaining the structural integrity and functional stability of the firearm's rear sight/handle assembly, underlining its importance in the effectiveness and reliability of the firearm's sighting system.

42. Forward Assist Spring Pin

The Forward Assist Spring Pin is an integral part of a firearm's forward assist mechanism, tasked with securing the forward assist plunger in its designated housing. This small but vital component plays a key role in ensuring the plunger's correct alignment and functionality, which is crucial for the effective operation of the forward assist system.

- Material: Constructed from durable materials, the spring pin is designed to endure the pressures and movements associated with the forward assist's operation, ensuring longevity and reliability.

- Function: Its primary role is to hold the forward assist plunger in place, ensuring it remains properly aligned within its housing. This alignment is crucial for the plunger's effective engagement with the firearm's bolt, allowing the forward assist mechanism to function as intended.

- Role in Operation: The Forward Assist Spring Pin is essential for the correct operation of the forward assist mechanism, which is used by shooters to manually ensure the bolt is fully closed and locked. This mechanism is particularly important for ensuring the firearm operates reliably, especially in situations where a round must be securely chambered.

- Maintenance: Regular maintenance is necessary to ensure the spring pin remains in optimal condition. This includes checking for signs of wear or damage and ensuring that the pin retains its structural integrity to continue providing reliable support for the forward assist plunger.

By securing the forward assist plunger effectively, the Forward Assist Spring Pin ensures the consistent functionality and reliability of the forward assist mechanism, underscoring its importance in the overall operation and safety of the firearm.

43. Forward Assist Plunger

The Forward Assist Plunger is an essential element of the forward assist mechanism on a firearm, allowing the user to manually ensure the bolt's complete engagement and lock-in. This component is crucial for the firearm's functionality, particularly in instances where the bolt has not fully seated.

- Material: Constructed from durable materials, the plunger is designed to withstand repeated use and apply consistent pressure to the bolt, ensuring its longevity and reliability in the firearm's operation.

- Function: Its main function is to be manually pressed or pushed by the user, which in turn engages the bolt and ensures it is fully seated and locked in place. This is especially vital in scenarios where the bolt has not fully closed, ensuring the firearm is ready and safe to fire.

- Role in Operation: The Forward Assist Plunger is the user-interactive part of the forward assist mechanism, enabling manual intervention to confirm the bolt's full engagement. This action is crucial for the firearm's reliable performance, ensuring it operates correctly and maintains readiness for use.

- Maintenance: Regular inspection and maintenance are essential to ensure the plunger functions effectively. It should be checked for wear, proper alignment, and smooth operation to guarantee that it can consistently apply the necessary pressure to the bolt.

By providing a means for manual intervention to ensure the bolt's full engagement, the Forward Assist Plunger plays a vital role in the firearm's operational reliability and safety, making it a key component in the forward assist mechanism.

44. Pawl Spring Pin

The Pawl Spring Pin is a vital element in the pawl assembly of a firearm's forward assist mechanism, ensuring the pawl's proper placement and functionality. This pin is crucial for the smooth and efficient operation of the forward assist, contributing significantly to the mechanism's overall reliability and effectiveness.

- Material: Made from high-strength materials, the Pawl Spring Pin is engineered to endure the mechanical stresses it encounters during the operation of the forward assist, ensuring its durability and sustained performance.

- Function: Its primary role is to maintain the correct positioning of the pawl within the forward assist assembly. This secure positioning is essential for the pawl's interaction with the bolt carrier, enabling the forward assist mechanism to function as intended, particularly in aiding the manual closure of the bolt.

- Role in Operation: The pin is integral to the forward assist's operation, allowing the pawl to engage effectively with the bolt carrier. This engagement is crucial for the manual actuation of the forward assist, ensuring that the bolt is fully seated and locked in place when necessary.

- Maintenance: Regular maintenance is vital to ensure the Pawl Spring Pin remains in optimal condition. This includes checking for wear or damage that could compromise the pawl's positioning or the forward assist's functionality, ensuring the firearm's readiness and operational safety.

The Pawl Spring Pin's role in maintaining the pawl's positioning and ensuring the effective operation of the forward assist mechanism underscores its importance in the firearm's functionality, highlighting the significance of each component in the overall reliability and safety of the weapon.

45. Pawl Spring

46. Pawl Detent

The Pawl Detent is a crucial component within the pawl assembly of the forward assist mechanism on a firearm, playing a key role in the precise and effective operation of the forward assist. It functions in conjunction with the pawl spring to ensure the pawl's proper engagement and functionality.

- Material: Constructed from high-quality materials, the Pawl Detent is designed to withstand the pressures and movements involved in the forward assist mechanism, ensuring durability and reliability throughout its use.

- Function: The primary function of the Pawl Detent is to provide a specific engagement point for the pawl, ensuring it aligns correctly with the other components of the forward assist mechanism. It helps maintain the pawl in the right position, enabling it to exert the necessary pressure for effective engagement and smooth disengagement.

- Role in Operation: The detent is vital for the pawl's operation, working with the spring to provide the tension and positioning needed for the pawl to function correctly. This ensures that the forward assist can reliably help seat the bolt fully into the chamber, a critical aspect of the firearm's operation, especially in scenarios where manual assistance is required to ensure the bolt's complete engagement.

- Maintenance: Regular maintenance is essential to ensure the Pawl Detent continues to function effectively. This includes checking for wear, ensuring it is not damaged or out of position, and confirming that it provides the correct tension and alignment for the pawl's operation.

The interaction between the Pawl Detent and the pawl spring is fundamental to the forward assist mechanism's efficiency, underscoring the importance of each component in the reliable operation of the firearm's forward assist, contributing to the firearm's overall functionality and user's safety.

47. Forward Assist Pawl

The pawl is a spring-loaded component in the forward assist mechanism of a firearm, specifically designed to engage with the teeth on the side of the Bolt Carrier Group (BCG). This engagement allows the user to manually ensure the bolt is fully seated in the event of a partial or incomplete closure.

- Material: Constructed from durable materials, the pawl is built to exert the necessary pressure and engage firmly with the BCG, ensuring longevity and reliability in its function.

- Function: The primary purpose of the pawl is to interact with the BCG's teeth, enabling the shooter to manually advance the bolt into its fully seated position, ensuring the firearm is properly chambered and ready to fire.

- Role in Operation: In situations where the bolt does not fully close on its own, the pawl, activated by the forward assist mechanism, provides the necessary pressure to secure the bolt in place, aiding in the firearm's correct operation.

- Maintenance and Safety: Regular inspection and maintenance are crucial to ensure the pawl functions as intended. It's important to note that if the bolt does not close properly, forcing it with the pawl should only be considered in critical situations. In normal circumstances, a malfunctioning bolt indicates the need for inspection and repair by a qualified gunsmith to prevent potential malfunctions or hazards.

The pawl's function is integral to the forward assist mechanism, providing an essential manual override that ensures the firearm's bolt is fully engaged, contributing to the safe and reliable operation of the firearm in critical situations.

48. Forward Assist Spring Pin

The Forward Assist Spring Pin is an essential part of the forward assist assembly in a firearm, playing a key role in the mechanism's ability to function correctly. This component ensures the appropriate tension is applied within the assembly, crucial for the mechanism's proper operation and interaction with the firearm's bolt carrier group (BCG).

- Material: Made from resilient materials, the Forward Assist Spring Pin is engineered to provide consistent tension and withstand the rigors of repeated use, ensuring it maintains its effectiveness over time.

- Function: Its main function is to exert pressure within the forward assist assembly, specifically influencing the pawl's position. This ensures that the pawl is retracted and remains clear of the BCG during the firearm's regular operation, preventing any unintended engagement.

- Role in Operation: The spring pin is critical for the forward assist mechanism, allowing the user to manually ensure the bolt's full engagement when necessary. Simultaneously, it ensures that the forward assist's components, particularly the pawl, are retracted and do not interfere with the BCG during normal operation, thus safeguarding against undue wear or operational hindrances.

- Maintenance: Regular inspection and maintenance are vital to ensure that the Forward Assist Spring Pin functions optimally. This includes checking for signs of wear or fatigue and ensuring that it continues to provide the necessary tension for the forward assist assembly to operate effectively.

By maintaining the correct tension and functionality within the forward assist assembly, the Forward Assist Spring Pin is indispensable for the mechanism's reliability, ensuring it is available to aid the firearm's operation when required while avoiding interference during standard cycling processes.

49. Upper Receiver

50. Ejection Port Cover Pin

The Ejection Port Cover Pin is an integral component of a firearm, specifically designed to secure the ejection port cover to the upper receiver. This pin not only ensures that the cover remains in place but also acts as a pivotal hinge, allowing the cover to rotate.

- Material: The pin is crafted from robust materials to endure the mechanical actions and environmental stress it encounters during the operation of the firearm.

- Function: Its primary function is to provide a secure attachment point for the ejection port cover, enabling it to pivot open or closed. When the firearm discharges, this pin allows the cover to open, facilitating the ejection of spent casings. Conversely, when the firearm is idle, the cover can be shut to shield the internal mechanisms from contaminants like dirt and debris.

- Role in Operation: The Ejection Port Cover Pin is crucial for the smooth operation and alignment of the ejection port cover with the upper receiver. This alignment ensures that the cover operates without hindrance, maintaining the firearm's functionality and protecting its internal parts.

- Maintenance: Regular inspection and maintenance of the Ejection Port Cover Pin are essential to preserve its functionality and the overall integrity of the firearm. This includes checking for signs of wear or damage and ensuring that the pin and cover operate smoothly.

The Ejection Port Cover Pin plays a vital role in the firearm's mechanism, particularly in the operation and maintenance of the ejection port cover, underscoring its importance in the firearm's performance and reliability.

51. Ring, Retaining Cover

The Retaining Ring, often referred to as the Ring, Retaining Cover, is a small but essential component designed to secure the Ejection Port Cover Pin within the firearm. It ensures that the pin remains firmly in place, preventing it from dislodging during the operation of the firearm.

- Material: Crafted from durable materials, the retaining ring is engineered to withstand the dynamic forces it encounters during the firearm's operation, maintaining its integrity and function over time.

- Function: The primary role of the Retaining Ring is to anchor the Ejection Port Cover Pin, ensuring it stays attached to the upper receiver. This is vital for the stability and functionality of the ejection port cover, as the pin is the component around which the cover pivots.

- Role in Operation: By securing the Ejection Port Cover Pin, the retaining ring indirectly contributes to the reliable operation of the ejection port cover. It ensures that the pin does not dislodge, allowing the cover to function correctly—opening to eject spent casings and closing to protect the firearm's internal components.

- Maintenance: Regular checks are essential to ensure that the Retaining Ring is not worn or damaged, which could compromise the pin's security. Proper maintenance ensures the longevity and reliable operation of this component and, by extension, the ejection port cover mechanism.

The Retaining Ring plays a pivotal role in maintaining the structural integrity and operational reliability of the firearm's ejection port cover system, highlighting its significance in the overall functionality of the weapon.

52. Ejection Port Cover Spring

The Ejection Port Cover Spring is a crucial component in the functionality of a firearm's ejection port cover. It provides the necessary tension and force to swiftly open the cover and maintains it in an open position, ensuring that it does not rattle, shake, or close accidentally during firearm operation.

- Material: Made from high-grade spring steel, the Ejection Port Cover Spring is designed for resilience and durability, ensuring it maintains its tension and structural integrity even under repeated use.

- Function: The spring's primary function is to facilitate the rapid opening of the ejection port cover when the firearm is discharged. It exerts a force that propels the cover open, allowing spent casings to be ejected without obstruction. Additionally, it holds the cover in the open position, preventing unwanted closure that could interfere with the firearm's operation or cause noise through rattling.

- Role in Operation: The Ejection Port Cover Spring is vital for the seamless performance of the ejection port cover. It ensures that the cover operates efficiently, opening promptly when required and remaining open during firing, thus contributing to the overall reliability and functionality of the firearm.

- Maintenance: Regular inspection and maintenance of the Ejection Port Cover Spring are essential to ensure its effectiveness and durability. This includes checking for signs of wear, loss of tension, or damage, as a compromised spring could affect the operation of the ejection port cover.